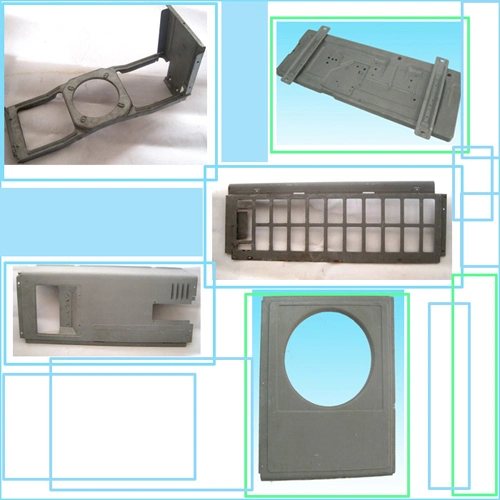

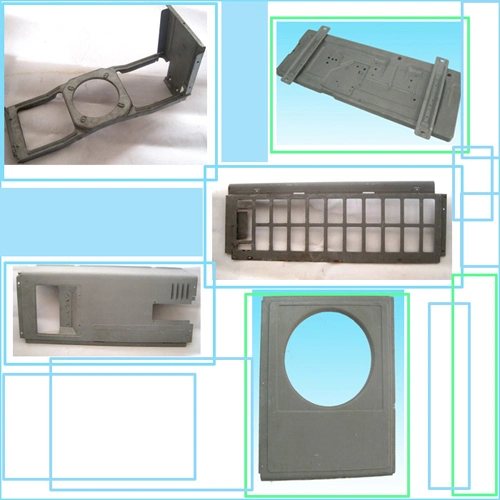

{Product material}: SPCC, SUS304 and so on

{Scope of application}: Home appliances

{Products MOQ}: 10000 part

{Die types}: Single process

{Tolerances}: 0.01

{Spare parts}: PUNCH, MISUMI and so on

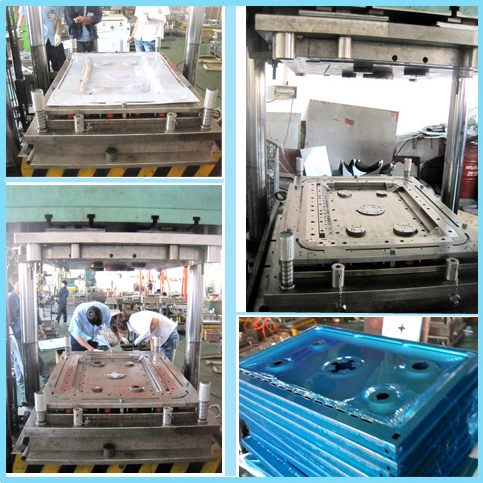

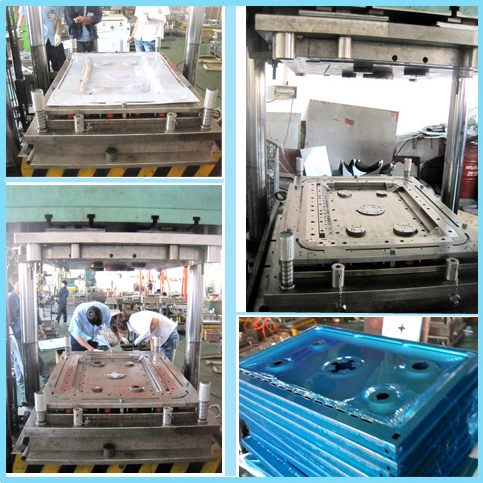

{equipment}: 400T Punch

{Produce equipment}: 315T Hydraulic machine/press, 400T\200T\160T Punch (With the belt feeding machine), 110T, 80T, 40T Punch equipment, Can meet the need of mass production and testing.

{Service content}: Designing and manufacturing for metal mould and products.

{Main customers}: Haier, Hisense, Midea, Siemens, SANYO, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}: Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina; South Africa Egypt; Iran, Pakistan, India etc...

{Mold paint}: Painting color depends on customer requirements

(Packaging: Wooden case)

The first trial success rate is above 95%

{Quotation time}: We will quote in 24 hours after receiving the customer's drawings.

{Data needed to offer}: 2D/ 3D drawing or samples

{Quotation}: Including the accurate price/stage/life and process time.

{The profile}: 2D/3D drawing or samples

{Project Manager}: Concentrate on project tracking and after service

{Engineer}: 30-50 excellent engineers, have many years experience and English communicate well.

{Warehousing and logistics}: The purchase department use EPR system to make sure buying materials in time.

{Fitter technician}: 100-130 experienced workers can meet the customer request of batch production.

{Quality department}: 15 members quality control workers, measuring the mould and parts by CMM and projector.

{Domestic delivery}: Logistics transportation

{Delivery to overseas}: FOB/CIF/DDU by sea shipping or air shipping

{Scope of application}: Home appliances

{Products MOQ}: 10000 part

{Die types}: Single process

{Tolerances}: 0.01

{Spare parts}: PUNCH, MISUMI and so on

{equipment}: 400T Punch

{Produce equipment}: 315T Hydraulic machine/press, 400T\200T\160T Punch (With the belt feeding machine), 110T, 80T, 40T Punch equipment, Can meet the need of mass production and testing.

{Service content}: Designing and manufacturing for metal mould and products.

{Main customers}: Haier, Hisense, Midea, Siemens, SANYO, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}: Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina; South Africa Egypt; Iran, Pakistan, India etc...

{Mold paint}: Painting color depends on customer requirements

(Packaging: Wooden case)

The first trial success rate is above 95%

{Quotation time}: We will quote in 24 hours after receiving the customer's drawings.

{Data needed to offer}: 2D/ 3D drawing or samples

{Quotation}: Including the accurate price/stage/life and process time.

{The profile}: 2D/3D drawing or samples

{Project Manager}: Concentrate on project tracking and after service

{Engineer}: 30-50 excellent engineers, have many years experience and English communicate well.

{Warehousing and logistics}: The purchase department use EPR system to make sure buying materials in time.

{Fitter technician}: 100-130 experienced workers can meet the customer request of batch production.

{Quality department}: 15 members quality control workers, measuring the mould and parts by CMM and projector.

{Domestic delivery}: Logistics transportation

{Delivery to overseas}: FOB/CIF/DDU by sea shipping or air shipping

| Step | Item | Description |

| 1 | Quotation | We offer you the impeller injection mould and part quotation according to your details(drawing or sample,material,quantity,weight). |

| 2 | Order | If our quotation is competitive,you will place the order. |

| 3 | Drawing design | We design the mould structure drawing according to your product drawing or sample,then send to you for confirmation. |

| 4 | Mould making | After your confirmation of our drawing,we begin to make the moulds,during manufacturing program,we send you mould building progress with pictures every week,for you to know our process. |

| 5 | First trial | We will make the mould first trial on time, then send you video, picture and samples for you to confirm. |

| 6 | Quality confirm | You will confirm our mould quality according to sample. If you need to adjust the product structure,we can help you change the mould further. |

| 7 | Delivery | Ship the mould after it is completely OK,packed by wooden case. |