Twin Screw Loss-in-weight Feeders for Powder Blending

General Introduction

Loss-in-weight feeders can be used for both small to medium feeding ranges. They work with extreme precision under optimum ambient conditions. They are very flexible and can handle bulk solids, liquids and even poorly flowing products. They are used in many continuous processes such as feeding extruders requiring a high level of short-term feeding consistency. They are also used in the food industry and in laboratories by means of appropriate storage containers and adapted feeding devices. The design varies from compact constructions to modular concepts depending on usage.

Principle

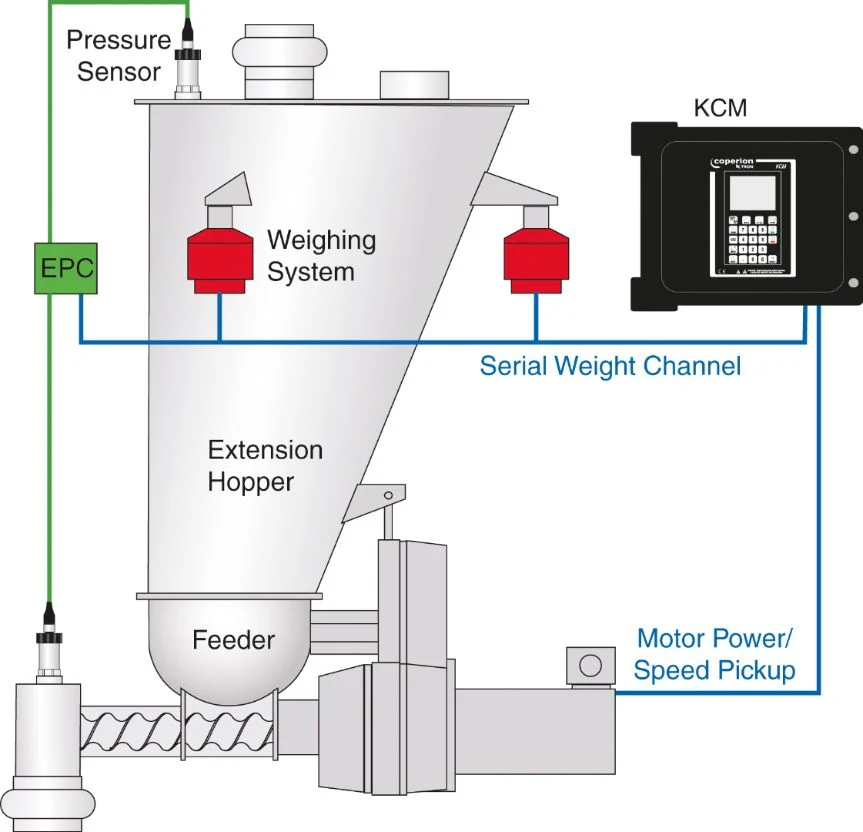

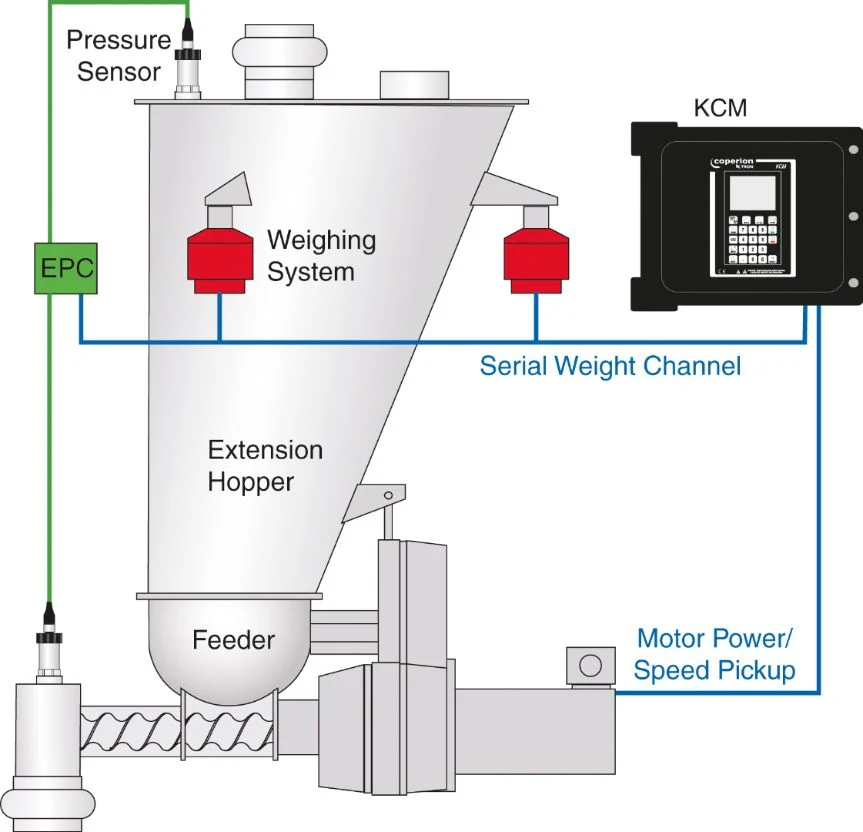

When the material is fed through the feeder, the weight of the system decreases. Controlling the loss-in-weight feeder changes the feed rate and as a result the speed of weight loss matches the desired feed rate. Loss-in-weight feeder controls continuously check whether the material is flowing.

All components and/or any product they contain is continuously weighed during operation: the feeder, the hopper and the material.

Gravimetric feeders, for instance, have slight fluctuations in their feed rates. These fluctuations occur in the filling capacity of the augers and in the bulk density of the material. These are compensated for by adapting the auger speed in order to ensure the product is dispensed evenly.

Company Profile

Nanjing Pege Techno Machine Co., Ltd has been working with bulk ingredients feeding, weighing for more than 10 years. We have gained knowledge and have become a reliable feeder supplier for various customers.

Whether for use in the plastics, chemical, pharmaceutical, food, pet food, detergent, ceramics, glass or construction material industries - the customer and his requirements are most important. Before we submit a quotation, we analyze your ingredient and work with you to determine your needs. Continuing this with our 10 years of experience we select the best device from our extensive product line which can feed any conceivable ingredient. All our machines can be further modified to fit the individual needs of our customers.

Besides extensive process advice we have many services such as feeding trials in our test labs, start-ups and operator training on site or at our training center.

We also offer maintenance, customized screws, spare parts and repairs as parts of our comprehensive after-sales services at reasonable prices.

Principle

In loss-in-weight feeding, the entire feeder, hopper and material are continuously weighed. As the feeder discharges material, the rate of decline in system weight is computed, and feeder speed is adjusted to maintain the desired (set) rate.

Twin Screw Loss-in-weight Feeders

Application material

Resin Granules, Resin Powder, Calcium carbonate, French Chalk, Tio2, Carbon Black

Features

Specifications

MM

Micro Type Twin Screw Feeder Specifications

FAQs

To reduce the labor cost and improve labor work environment

To Improve product stability

Reduce dust pollution and be more environmentally friendly

General Introduction

Loss-in-weight feeders can be used for both small to medium feeding ranges. They work with extreme precision under optimum ambient conditions. They are very flexible and can handle bulk solids, liquids and even poorly flowing products. They are used in many continuous processes such as feeding extruders requiring a high level of short-term feeding consistency. They are also used in the food industry and in laboratories by means of appropriate storage containers and adapted feeding devices. The design varies from compact constructions to modular concepts depending on usage.

Principle

When the material is fed through the feeder, the weight of the system decreases. Controlling the loss-in-weight feeder changes the feed rate and as a result the speed of weight loss matches the desired feed rate. Loss-in-weight feeder controls continuously check whether the material is flowing.

All components and/or any product they contain is continuously weighed during operation: the feeder, the hopper and the material.

Gravimetric feeders, for instance, have slight fluctuations in their feed rates. These fluctuations occur in the filling capacity of the augers and in the bulk density of the material. These are compensated for by adapting the auger speed in order to ensure the product is dispensed evenly.

Company Profile

Nanjing Pege Techno Machine Co., Ltd has been working with bulk ingredients feeding, weighing for more than 10 years. We have gained knowledge and have become a reliable feeder supplier for various customers.

Whether for use in the plastics, chemical, pharmaceutical, food, pet food, detergent, ceramics, glass or construction material industries - the customer and his requirements are most important. Before we submit a quotation, we analyze your ingredient and work with you to determine your needs. Continuing this with our 10 years of experience we select the best device from our extensive product line which can feed any conceivable ingredient. All our machines can be further modified to fit the individual needs of our customers.

Besides extensive process advice we have many services such as feeding trials in our test labs, start-ups and operator training on site or at our training center.

We also offer maintenance, customized screws, spare parts and repairs as parts of our comprehensive after-sales services at reasonable prices.

Principle

In loss-in-weight feeding, the entire feeder, hopper and material are continuously weighed. As the feeder discharges material, the rate of decline in system weight is computed, and feeder speed is adjusted to maintain the desired (set) rate.

Twin Screw Loss-in-weight Feeders

Application material

Resin Granules, Resin Powder, Calcium carbonate, French Chalk, Tio2, Carbon Black

Features

- Cantilever type weighing frame ensure lower gravity(barycenter) center, weaker vibration and anti-interference performance of the whole feeder.

- Vertical U-shaped hopper with mirror-like inner wall and without corner enclosure can ensure no bridge of the materials

- Stainless Steel bellow sensor has the feature of only slight deformation after long time use, and high precision with less signal drift, and is durable for bad environment use

- 485 Digital transmission of weighing data has the feature of no attenuation and anti-interference during the period of data transmission.

- Feeding and stirring is operated separately, using independent agitation motor and stirring speed can be adjusted according to the demand.

- No agitation motor on the top of the hopper will surely reduce the vibration during the operation, then this design will achieve high stability and high accuracy.

Specifications

| Parameters Model | FT-28 | FT-38 | FT-46 | FT-64 |

| Capacity range | 20-100kg/h | 50-300kg/h | 100-600kg/h | 200-1200kg/h |

| Volume | 40L | 100L | 150L | 250L |

| Range | 50kg | 100kg | 150kg | 200kg |

| Net Weight | 86kg | 140kg | 170kg | 190kg |

| Size | 550x340x680 | 680x430x900 | 790x480x1050 | 950x530x1270 |

| Power | AC380V Feeding motor 0.25kw +stirring motor 0.15kw | AC380V 3ph Feeding 0.37kw +Stirring 0.2kw | AC380V 3ph Feeding 0.55kw +stirring 0.4kw | AC380V 3ph Feeding 0.75kw +Stirring 0.75kw |

| Screw | Solid Twin Screw | Solid Twin Screw | Solid Twin Screw | Solid Twin Screw |

| Dynamic accuracy | ±0.5% | ±0.5% | ±0.5% | ±0.5% |

| Resolution | 1/100000 | 1/100000 | 1/100000 | 1/100000 |

| Discharge tube | Φ45x3x2 | Φ57x3x2 | Φ65x3x2 | Φ89x3x2 |

Micro Type Twin Screw Feeder Specifications

| Parameters Model | FT-15 | FT-20 |

| Capacity range | 0.5-3kg/h | 2-15kg/h |

| Volume | 5L | 8L |

| Range | 3kg | 5kg |

| Net Weight | 40kg | 50kg |

| Size | 510x340x480 | 530x360x480 |

| Power | AC220V 1ph Feeding Servo Motor 0.1kw Stirring Servo Motor 0.1KW | AC380V 3 Feeding Servo Motor 0.2kw Stirring Servo Motor 0.2KW |

| Screw Type | Solid Twin Screw | Solid Twin Screw |

| Dynamic accuracy | ±0.5% | ±0.5% |

| Resolution | 1/100000 | 1/100000 |

| Discharge tube | Φ26x3x2 | Φ30x3x2 |

FAQs

- How does loss in weight feeder works?

- What are the most important benefits the gravimetric feeder can give to you?

To reduce the labor cost and improve labor work environment

To Improve product stability

Reduce dust pollution and be more environmentally friendly

- What is general accuracy rate of the good loss in weight feeder?

- What is the main composition of a typical loss in weight feeder?