MORN LASER Hand-held Fiber Laser Welding Machine Wobble Head with Auto Wire Feeder System

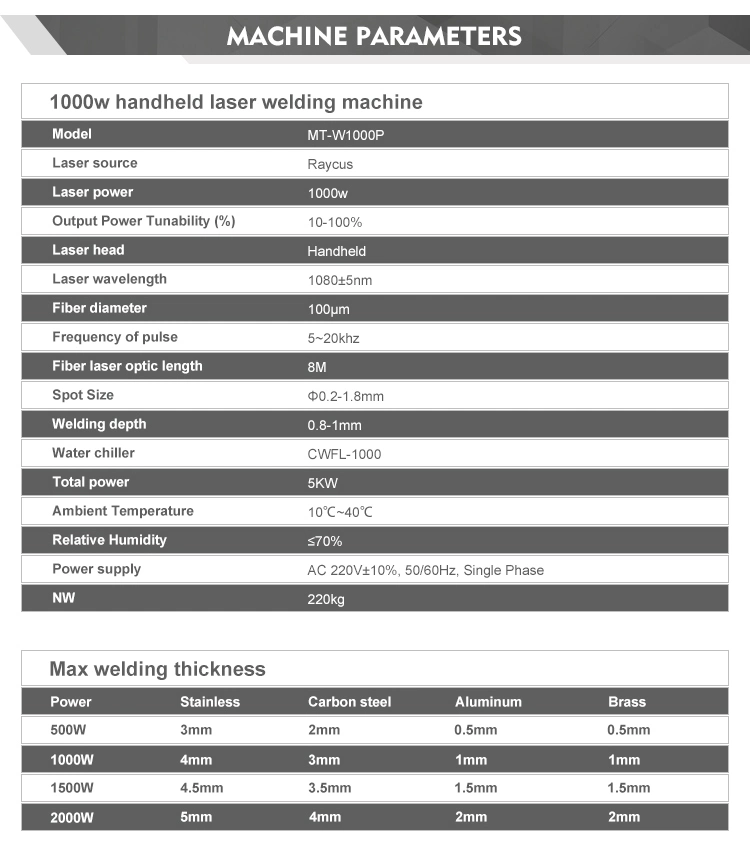

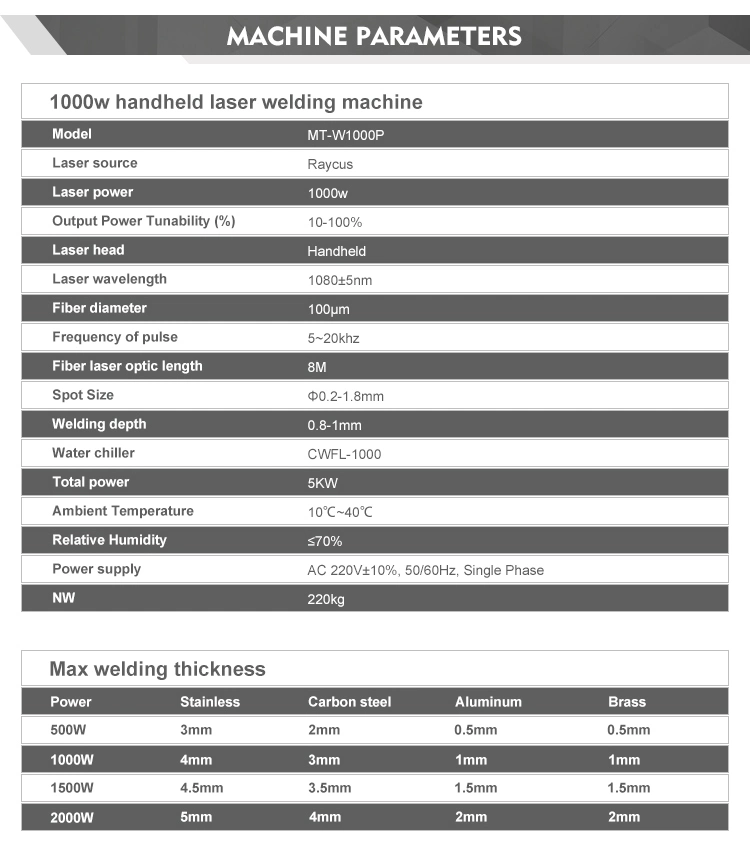

Parameter:

| Power | stainless steel | galvanized/carbon steel | Aluminum | Brass |

| 1000W | 4mm | 3mm | 1mm | 1mm |

| 1500W | 4.5mm | 3.5mm | 1.5mm | 1.2mm |

| 2000W | 5mm | 4mm | 2mm | 2mm |

Bullet points:

Flexible Operation: Hand-held fiber optic transmission laser welding machine has a 8-meter-long imported fiber optic connection laser head, it can be long-distance welding on the product that is large and not easy to move.

Easy Operaion: The operation is simple, easy to learn, the operator's technical threshold is not high, saving the labor cost.

High Efficiency: Large welding depth, firm and beautiful appearance, full melting, no traces, no bulges or dents Small heat-affected zone, won't cause deformation of the mold. No secondary processing, improve work efficiency, and quickly earn money back.

Firm and Beautiful Welding Joints: No deformation or welding scar, firm welding of the workpiece. Smooth welding seam and beautiful, large depth, small taper, reduce subsequent griding process, don't need polish, save time and cost. Small heat affected zone, flat welding joints, welding intesity and toughness are similar or even exceeded to base metals.

Low Cost: 80% to 90% power savings, processing costs are reduced by 30%. Laser welding has less consumables, low energy consumption and long service life

Safety: When the gun head does not touch the workpiece, there no laser is emitted, only red light is emitted, and when the gun head touch the workpiece and the ground clamp is turned on, then the laser work. Also the machine equipped with professional laser safety glasses

Application:

Laser Welding Machine Applied Materials: Titanium, aluminum, copper, zinc, gold, sliver and many other metal and alloy, carbon steel and stainless steel materials, and also cooper-brass, cooper-titanium, nickel-cooper, cooper-titanium and many other heterogeneous metals. (Kindly let us know your materials thickness, we will offer you the most suitable configuration)

Laser welding can be used in welding stainless steel, aluminum, copper, chromium, nickel, titanium and other metals or alloys. Laser welding is widely used in the IT industry, medical equipment, communications equipment, aerospace, machinery manufacturing, battery manufacturing, elevator manufacturing, craft gifts, household appliances manufacturing, tooling, gears, automobile shipbuilding, and other industries.

Laser Welding Machine Application: It is widely used in aviation, machinery, electronics, mobile phones, communications, chemicals, electrical appliances, hardware, automotive manufacturing,

Gurantee:

Guarantee: 2-year warranty for whole machine, generator for 2 years. (Not include consumable parts). Lifetime online technical support. If you have any question just contact us via e-mail, we will provide you with the best after-sale service.

Machine order process:

1. Confirmation of customer requirements by 3D drawing;

2. Parts warehousing inspection;

3. Delivery confirmation;

4. Machine process;

5. Debug the machine;

6. Material cutting test;

7. Sample test;

8. Machine cleaning;

9. Package and delivery;

10. Container sealing;

11. Transportation tracking;

12. Oversea training, and received good comments from customers.

Customer visits & Exhibition:

Certificate:Machine order process:

1. Confirmation of customer requirements by 3D drawing;

2. Parts warehousing inspection;

3. Delivery confirmation;

4. Machine process;

5. Debug the machine;

6. Material cutting test;

7. Sample test;

8. Machine cleaning;

9. Package and delivery;

10. Container sealing;

11. Transportation tracking;

12. Oversea training, and received good comments from customers.

Customer visits & Exhibition:

Our laser machine has passed international CE and FDA certification.

Company profile:

Jinan MORN Technology Co.,Ltd. is committed to the R&D, production and sales of laser cutting, marking, cleaning and welding equipment, and provides all-round laser solutions. It is one of the few companies in China which have independent research and development capabilities and of the earliest enterprises which provide high-tech equipment integrating optics, mechanics and electronics. All series of products have passed CE, FDA and other international certifications.

Q&A:

1. Is the welding machine is easy to operate?

Yes, the operating system can be set in English, And you just need to set some different parameters on the screen. There's no problem to learn how to use it in few hours.

2. Does the machine need ausiliary gas?

Yes, Nitrogen and Argon both are OK.

The gas isolate the air from the welding plate to prevent reaction with the air. So the welding surface of the metal plate will be white and beautiful. The gas can protect the lens from welding dust.

3. How to ensure the safety of the handhels laser welder?

1)Machine system includes safety protection, And machine will work only when the clip and the welding head(gun) contact with metal at the same time, which can protect the operator's safety.

2)High temperature resistant gloves

When you use the machine, please ware gloves for double safe.

3)Goggles

Machine come with Goggles for eye protection, we consider every details for customers.

4. What's the advantages of the wobble welding head?

With wobble head, the width of the gap that can be reach to 0.5mm.